Choose my battery charger

As a manufacturer of battery chargers, we generally recommend calibrating a charger at around 10% of the service park for Lead batteries.

Example: a 25A charger is recommended for a service park between 200 and 300Ah.

However, increasing this ratio may be justified in certain cases:

– Specific battery technology (i.e. Lithium LiFe PO4 with BMS / Recommended Ratio 30%).

– The need for additional energy to supply constant DC consumers (i.e. return from sea, short stopover, discharged batteries, you remain on the boat and a certain number of consumers are in operation): the charger must then be sufficiently powerful to recharge batteries and supply consumers.

The starter battery is not taken into account, because it is only very slightly discharged. Indeed, being naturally recharged by the alternator, the starter battery does not consume much current.

It is always preferable to dedicate a charger to batteries of the same technology.

This optimizes charging performance to 100% and therefore extends the life of the batteries.

However, the reality of the installations is often different. In our case, we supply our chargers to shipbuilding yards.

They often use Sealed Lead for the starter battery, AGM for the thruster, and now optional Lithium for service.

As such, we have worked in close collaboration with battery manufacturers, to offer a satisfactory charge profile, which allows this mix of technologies.

In this case, we advise you to keep the factory setting of the charger.

CRISTEC chargers are compatible with Lithium Iron Phosphate (LiFePO 4) technology batteries with integrated BMS (Battery Management System).

- LiFE PO4 batteries present 3 x major advantages:

- Weight / bulk saving Autonomy thanks to the high discharge rate (90%)

- Fast charging with a suitable charging current

These are batteries that absorb a very high current when charging. It is therefore necessary to ensure, within the framework of the adaptation of an existing installation, to dimension accordingly:

- The battery charger (C / 3: example 25A model for 90Ah).

- The alternator

- Cable sections

In the case of specific Lithium batteries, please consult CRISTEC.

This option makes it possible to adapt the charging voltage of the charger according to the ambient temperature of the battery room. This allows for optimized battery charge and improves battery life. We can offer you two solutions, which can be deployed individually or be shared: Addition of an STP temperature sensor which will be connected to the charger: The latter will be placed in the battery room, as close as possible to the battery, on one of the cables, outside the box. This option is particularly recommended when the batteries are in a high temperature environment (confined room, high outside temperature, etc.).

We have chosen to market separate functions: charger and converter (= inverter):

- Combis are attractive in terms of size. However, separate functions are more secure: in the event of a breakdown on a combi, you lose the AC and DC on board

- Combis often have only 2 load outputs, with one being limited in current

- The charging curves available are generally less elaborate than on a quay charger

Install my battery charger

We recommend that you install your charger as close as possible to your batteries, in order to avoid voltage drops on the DC cables.

Living spaces: CRISTEC chargers are mostly fanless, which allows you to install them in living spaces (eg berths).

For models with a fan, our remote touch screen display (YPO-DISPLAY-R offered as an option) has a night mode which allows the fan to be inhibited for 8 hours (YPOWER 12V 60A and 24V 30A models).

Engine room: CRISTEC chargers operate at full load up to a temperature of 60 ° C without any loss. On the other hand, our YPOWER 12V 40A model is ISO8846 certified (protection against the ignition of flammable gases), which allows you to install it in the engine area, near a tank.

If you have an engine battery and a service battery, you must connect:

- The engine battery with + BAT E (or + BAT D depending on generation)

- The service battery either on + BAT 1 or + BAT 2

- The unused positive output will remain in the air

- The negative will be common to both batteries

CRISTEC chargers can easily be installed in parallel, in order to increase their capacity.

We recommend using chargers of the same model and caliber. The length of the output cables, as well as their cross-section, must also be identical (star-shaped equipotential assembly).

The presence of LIN on certain versions (HPOWER, YPOWER DC-DC) allows totally balanced installations of master-slave type.

CRISTEC chargers are designed to be installed on a vertical wall while maintaining a 150mm area around the charger.

You have the option of installing them horizontally, but in this case IP protection will be impacted and thermal cooling will no longer be optimized.

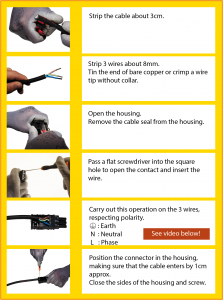

The alternative input must be made on a WAGO WINSTA type connector reference 770-103 (not supplied for OEM version).

Set my battery charger

The choice of batteries has become particularly diverse in recent years. Batteries of different technologies and components can be found on the market. It is essential to ensure that the charge profile is perfectly suited to the type of batteries.

Our chargers are equipped with devices * allowing configuration according to the type of batteries and the application. Refer to the corresponding manual.

For YPOWER or HPOWER models, it is possible to select the charging profile via the remote display option (YPO-DISPLAY-R or HPO-DISPLAY-R or UNI-DISPLAY-R).

* Micro-switches, encoder wheel or push button depending on model.

Our chargers are configured by default when leaving the factory for sealed lead batteries *.

We have worked in close collaboration with battery manufacturers to offer a charge profile that meets the needs of recharging a mixed banks: sealed lead *, AGM, gel, lead calcium and spiral lead.

* Closed electrolyte without maintenance

For certain special cases, it is possible to deactivate the Boost via the device provided for this purpose. Refer to the corresponding manual.

This function is available on the YPOWER and HPOWER ranges.

This is an automatic weekly cycle (whether or not inhibited using microswitch F) which optimizes the life of the battery.

It only intervenes after a complete recharge cycle (BOOST, ABSORPTION and FLOATING).

The charger will automatically generate a timed voltage step every 7 days regardless of the position of the Boost microswitch.

This makes it possible to limit the risks of sulphation of the plates, in particular when the service banks are composed of several elements mounted in parallel and when the latter remain permanently subjected to a floating type load regime.

Be sure to check with the battery manufacturer that this function is compatible with them (some types of AGM batteries do not support this function).

Use my battery charger

Each charger output has a non-return device.

There is therefore no risk in starting the engine or having another charging source (solar regulator, wind turbine, etc.) which is charging with the charger running.

You can leave your CRISTEC charger connected at all times.

For long periods of inactivity, you also have the option of selecting the Wintering setting at the level of the battery type selection devices *.

* Micro-switches, encoder wheel or push button depending on model.

CRISTEC battery chargers are equipped with a universal AC input (from the CPS2 range).

This system allows them to operate automatically and indifferently from all single-phase networks from 90 to 265VAC and from 47 to 65Hz.

This makes it easier to use your charger all over the world, without any intervention!